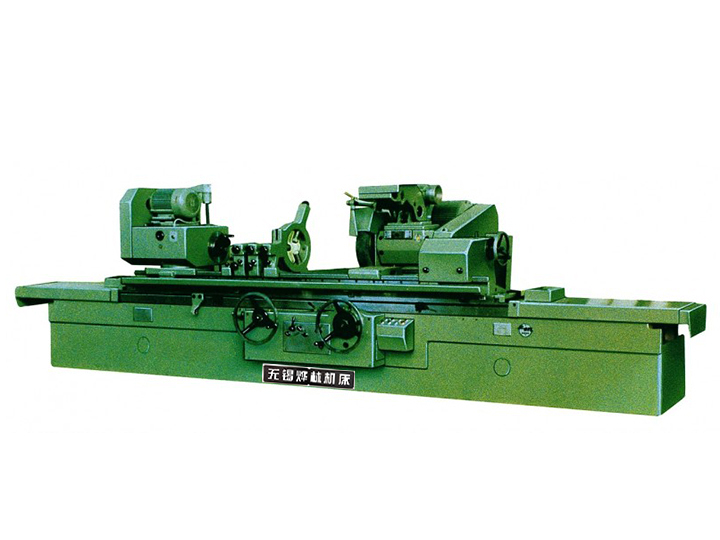

A core drilling rig is an indispensable piece of equipment in numerous engineering and scientific research fields. Its core function is to precisely drill and obtain cylindrical core samples from various materials of different properties. Unlike traditional drilling methods that rely on impact or cutting, core drilling rigs primarily operate through a precision grinding process. This characteristic allows them to maximize the integrity of core samples while drilling, providing valuable physical evidence for subsequent analysis and research.

Main Types of Core Drilling Rigs

Core drilling rigs can be categorized into the following types based on their design features and application scenarios:

1. Portable Core Drilling Rigs: These rigs are characterized by their compact size and flexibility, typically designed for handheld operation. They are ideal for use in confined spaces with limited working room or for operations requiring smaller drill hole diameters. Their ease of operation makes them stand out in scenarios needing quick and flexible drilling.

2. Frame-Mounted Core Drilling Rigs: Frame-mounted rigs are more suitable for cutting large structures, such as in construction and civil engineering projects where larger diameter holes need to be drilled. To ensure stability and resistance to torque during drilling, these rigs are usually firmly fixed on specialized stands or tracks.

3. Industrial Core Drilling Rigs: Industrial rigs primarily serve large-scale civil engineering projects, such as bridge construction and tunnel excavation. They can handle larger diameter drilling requirements and typically rely on more powerful power sources to meet industrial-grade operational intensity and efficiency demands.

Wide Application Fields of Core Drilling Rigs

With their unique functions, core drilling rigs play a crucial role in multiple fields:

Geological Exploration: In geological exploration, core drilling rigs are important tools for obtaining subsurface rock and soil samples. These samples help geologists gain in-depth understanding of key information such as subsurface geological structures, lithological characteristics, and mineral resource distribution, providing basic data for subsequent resource development and engineering planning.

Engineering Construction: In building construction and various civil engineering projects, core drilling rigs are often used to drill test cores from construction materials such as concrete and asphalt concrete. These cores are then sent to laboratories for a series of mechanical property tests, such as compressive strength and flexural strength, to evaluate the quality of building materials and structural safety.

Material Research: Core drilling rigs are also indispensable equipment in materials science research. By drilling samples of specific materials, researchers can conduct in-depth analysis of the material’s physical and mechanical properties, internal structure, and mineral composition, thereby promoting the development of new materials and the improvement of existing material performance.

How to Choose the Right Core Drilling Rig

Selecting a suitable core drilling rig requires comprehensive consideration of multiple factors to ensure it can meet specific operational needs:

Required Drilling Diameter Range: This is the first factor to consider when choosing a rig. The maximum drilling capacity of the rig should be determined based on the actual required hole diameter in the operation.

Rig Torque and Power: To ensure the rig can successfully complete the intended drilling tasks, especially when dealing with hard or complex materials, the rig must have sufficient torque output and power support.

Compatibility of Anchoring System: If the working environment requires an anchoring system to fix the rig, it is necessary to ensure that the selected rig is compatible with commonly used anchoring systems to ensure construction safety and drilling accuracy.

Reliability of Water Supply System: For operations using wet drilling methods, the water supply system equipped with the rig is crucial. It needs to ensure reliable water supply, preferably with an adjustable valve to control water volume according to different drilling conditions.

Overload Protection and Speed Regulation: Choosing a rig equipped with an overload clutch can effectively avoid damage to the equipment when the drill bit is accidentally stuck. At the same time, whether the rig’s speed is adjustable is also an important factor affecting drilling efficiency and quality.

Compatibility of Drill Bit and Spindle: Ensuring that the selected drill bit matches the thread specifications of the rig’s spindle is a basic condition for the smooth progress of drilling operations.

Stability and Quality of the Drill Stand: For frame-mounted rigs, the quality of the drill stand is directly related to the stability during drilling and the final drilling accuracy. A sturdy, durable, and structurally stable drill stand should be selected.

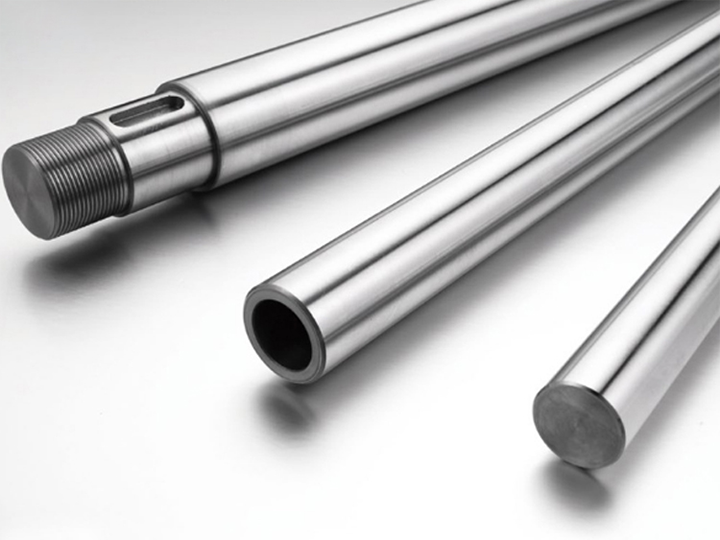

Core Advantages of Core Drill Bits

The widespread application of core drilling rigs is largely attributed to the design of their core drill bits, mainly reflected in the following aspects:

Obtaining Intact Core Samples: The most significant advantage of core drill bits is their ability to directly extract a complete section of core sample from the borehole. This provides geologists, engineers, and other professionals with intuitive and accurate information about the stratum or the interior of the material.

Improving Exploration and Analysis Accuracy: Through detailed analysis of the retrieved intact core samples, key geological parameters such as stratum lithology, thickness, groundwater level, and rock formation attitude, or various performance indicators of materials, can be more accurately determined.

Facilitating Laboratory Analysis and Testing: Intact core samples can be directly sent to laboratories for various professional tests such as lithological identification, physical and mechanical property testing, and mineral composition analysis, providing reliable data support for scientific research and engineering decision-making.

Adapting to Various Stratum Conditions: The design of high-quality core drill bits enables them to adapt to different types of strata, including soft rock, hard rock, and loose strata such as sand and clay, allowing effective drilling and coring.

Meeting Different Drilling Direction Requirements: Core drill bits are not only suitable for common vertical drilling but can also be used for inclined drilling and even horizontal drilling according to actual engineering needs.

Summary

In conclusion, as a powerful and widely used tool, core drilling rigs play an irreplaceable role in many fields such as geological exploration, engineering construction, and material research. When choosing a suitable core drilling rig, factors such as hole diameter requirements, type of working material, drilling depth, and on-site environment need to be carefully considered. Through correct operation methods and regular maintenance, core drilling rigs can help users efficiently and safely complete various drilling and coring tasks, providing strong technical support for the development and progress of related fields.”